In 2011, I moved to my current residence. Due to degenerative arthritis, I installed an electric stairlift in December 2012. As the local market wasn’t mature at that time, I eventually decided to purchase a European product, which I believe was from the UK.

It originally came with a two-year warranty and requires regular battery replacements. It uses two NP7-12 deep-cycle batteries connected in series for 24V power supply, typically needing replacement every 3-4 years. For the last two replacements, I did it myself since I had more time to study the process, saving the NT$2500 on-site service fee.

Recently, the lift suddenly stopped while going down and completely lost power. I initially thought the batteries had failed again (last replaced in 2022). As it was just entering summer and quite hot, I decided to wait until cooler weather to replace them. Last week when temperatures dropped, I promptly installed new batteries – but it still didn’t work.

Later I discovered the fuse was blown. Not having the small automotive fuse strips (only larger ones), I trimmed one to fit. However, it blew two consecutive fuses, confirming there must be an issue with either the control board or motor. I didn’t dare continue testing after seeing white smoke emerge from the red-circled area in the photo below. Through research, I learned this component is the electromagnetic brake attached to the motor, preventing movement when the chair is stationary.

The manufacturer’s service quoted approximately NT$65,000 for motor replacement and NT$45,000 for the control board if needed. Oh my god, that’s almost the price of a new unit!

I then studied the manual (better documented than my other unit, with clear circuit board diagrams but no motor details). Through online searching using the model number, I confirmed the red-circled part was indeed the electromagnetic brake.

Using my circuit repair experience, I reasoned that since fuses kept blowing, there must be a short circuit downstream. Then it occurred to me – this might be a brushed motor. After years of use, could the carbon brushes be worn out? I successfully guessed the brush location:

Inspection confirmed the carbon brushes were completely worn out.

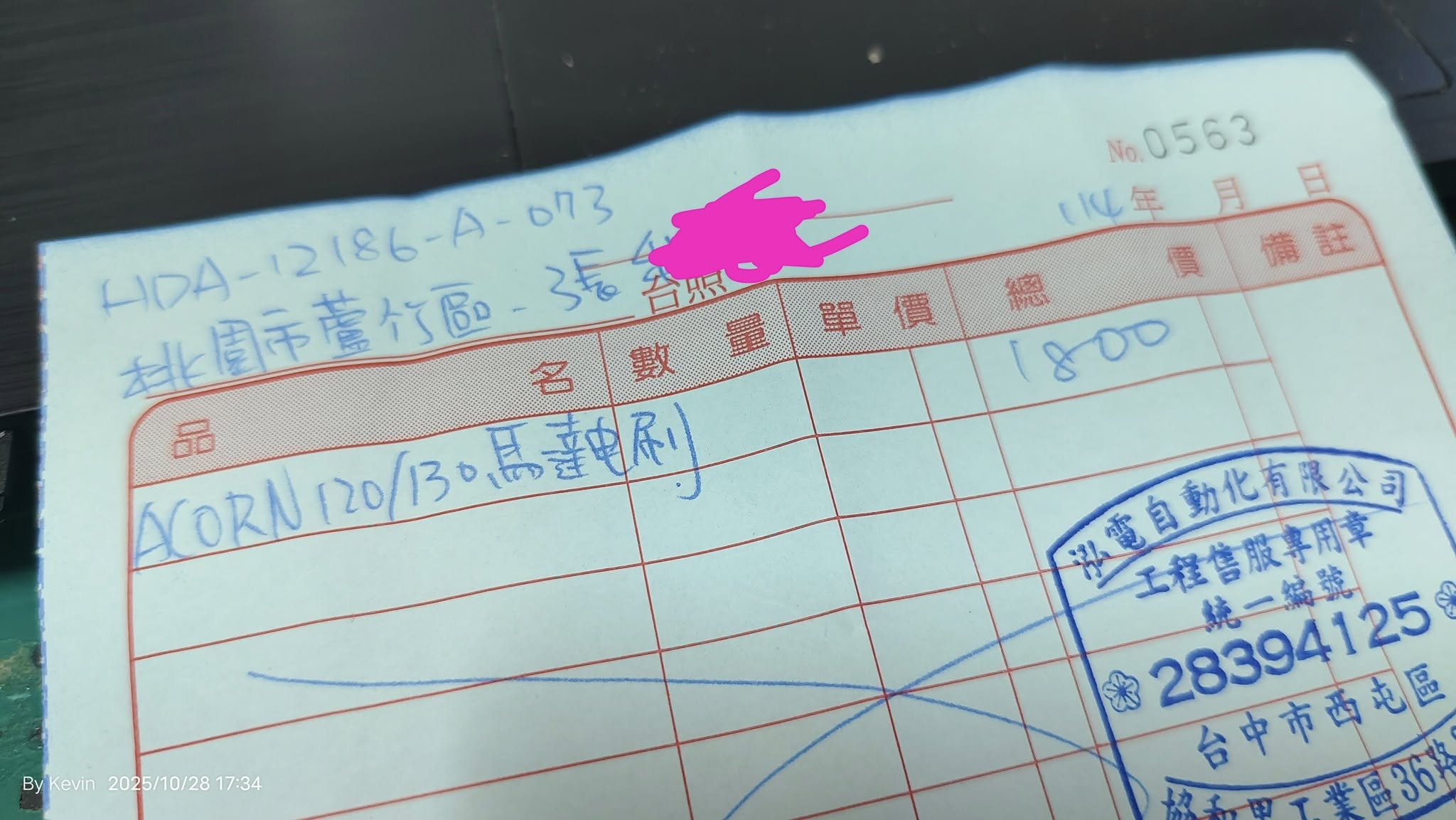

The manufacturer’s service was initially reluctant to sell me parts, perhaps doubting my diagnosis. I insisted they just sell me the parts, understanding it was at my own risk. They finally agreed to ship to their Taoyuan branch for pickup – NT$1,800 per set.

While I could theoretically make my own brushes, the dimensions were substantial. After careful measurements and comparing with OEM parts, I realized my measurements were slightly off. The NT$1,800 essentially paid for verifying specifications. Given the original brushes lasted 14 years, these should theoretically last a decade, assuming other components remain functional.

Installation proved challenging – one side was blocked by the wall, making it hard to apply force. I even stripped the screw head trying to remove it. After 2-3 hours of struggle, I drilled a hole and used an M2 self-tapping screw with pliers to finally remove it:

After successful installation, the lift worked perfectly again. Below is the test before reassembling the cover:

Completed repair photos:

Battery replacement tutorial video:

https://www.youtube.com/watch?v=InUOJkGdZpM

PS: I only provide informational content. Anyone attempting DIY repairs does so at their own risk. I cannot be held responsible for any outcomes. If you’re not technically proficient, we strongly recommend contacting official service technicians for repairs.